Recently Viewed Products

Customer Inquiry

+34-917957526

Weekdays 08:00-17:30

(Madrid Time)

(Madrid Time)

CHC Green Desing

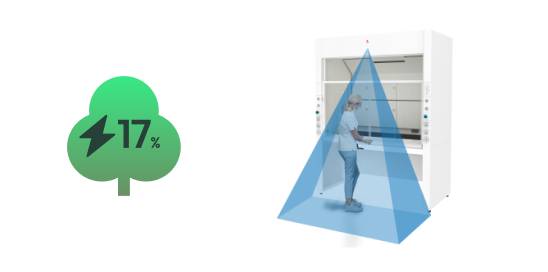

Vertical and Horizontal Sashes for Maximum Energy Efficiency

14.5% Enhanced Airflow

Consistent 0.3m/s Airflow for Reliable Performance in Any Environment, Anytime

Specification

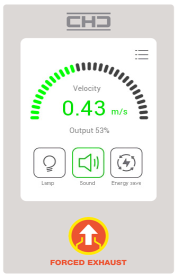

| 모델명 | CHC VAV Controller |

| 규격 (WⅩDⅹH, mm) | 80ⅹ130ⅹ30 |

| 풍속 측정 범위 | 0~1 m/s (±0.03 m/s) |

| 입력 전원 | AC 110 / 220V, 50 / 60 Hz |

| 출력 전류 | 0.5A |

| 통신 포트 | RS485 |

Specification

| Model | SCHNEIDER ICM500 |

| (WⅹDⅹH, mm) | 84ⅹ158ⅹ48 |

| Face velocity Measurement Range | 0.1~1 m/s (±0.015 m/s) |

| Power | AC 110 / 220V, 50 / 60 Hz, DC 15 V |

| Current | 0.12A |

| Communication Port | RS232 |

Unit: mm, Tolerance: ±5mm

| Section | XFL-BA | |||||

|---|---|---|---|---|---|---|

| 120 | 150 | 180 | 210 | 240 | ||

| Size (W×D×H, mm) | Outer | 1200×850×2365 | 1500×850×2365 | 1800×850×2365 | 2100×850×2365 | 2400×850×2365 |

| Inner | 995×675×1200 | 1295×675×1200 | 1595×675×1200 | 1895×675×1200 | 2195×675×1200 | |

| Material | Outer | Steel Plate (Epoxy Powder Coated) | ||||

| Inner | Phenolic Laminate | |||||

| Worktop | Epoxy 25 mm (option : Phenolic Laminate, STS, PVC, P.P.) | |||||

| Sash | Tempered Glass 5 mm | |||||

| Frame | Steel Pipe (Epoxy Powder Coated) | |||||

| Types of Sashes | Vertical sash (Option: Combination Sash) | |||||

| Cup Sink | 1 EA (Option: 2 EA) | |||||

| Power Socket | 220V×4EA (Left, Right 2EA each) | |||||

| Lamp (LED) | 25 W×1 EA | 25 W×2 EA | ||||

| Controller | CHC Monitor (Option: CHC VAV Contoller, Schneider Contoller, ON/OFF Switch) | |||||

| Earth Leakage Breaker | Ceiling Distribution Box (including Terminal Block and Earth Leakage Breaker)(option : Front Earth Leakage Breaker) | |||||

| Valves | Water×1EA, N₂×1EA (Option: Additional Valve 4EA) | |||||

| Exhaust Port | P.P. Ø250 (option : P.P. Ø300 / PVC Ø200, Ø250, Ø300) | |||||

| Power Consumption | 25 W | 50 W | ||||

| Options | Sash Safety Film | |||||

| STS RACK | ||||||

| PIR sensor (Auto Sash) | ||||||

| Lower Frame Built-in Cabinet | ||||||

| Blower | ||||||